The basic function of a dust collector in the cement industry

Cement production plants heavily rely on dust collectors that are represented in significant numbers. In most cases, the core of the cement plant is the Kiln and a dust collector connected to the Kiln. It is common practice that Kilns are running 24/7 all year round together with its primary filter collector.

Turning the Kiln off, during expected or unexpected downtime, represents huge costs for any cement plant. Therefore, it is very important for any manager to plan ahead, when maintenance should be done and constantly monitor operations of the Kiln, to determine if maintenance is required.

As a starting point, looking at our example of a cement plant, and the process where dust collectors are involved; you can find the 6 parts briefly described below and find where different parts play a role in the image under the descriptions.

1st part – Blending of the raw materials.

2nd part – In general, coal is the most used fuel on cement plants and most of the time the coal is being grinded. This could cause air pollution and put employees into a health risk.

3rd part – Use of Kiln: Pyro-processing exposes blended raw materials to high temperatures which causes chemical reactions that are turning raw materials to clinker.

4th part – Cooling down the clinker.

5th part – Cooler clinker is grinded into powder.

6th part – While handling the material in the packaging and shipping process it could potentially cause air pollution which means involving dust collectors is important for safety reasons.

The secondary dust collectors used for example in the mill grinding process have different maintenance plans than the core filters connected with the Kiln. Quite often practice is to have more than one piece of those secondary collectors either in operation process or on the stock. With this method, you can switch one dust collector for another and do the maintenance, while the secondary collector operates.

Why is proper maintenance of dust collectors important?

The proper maintenance of your dust collector can spare you of large expenses in energy consumption. In other words, if the maintenance is not done properly, you could experience an unplanned downtime which resolves in higher operating costs.

Here you can read 6 recommendations that are to be considered for your maintenance.

1. Monitoring your dust collector

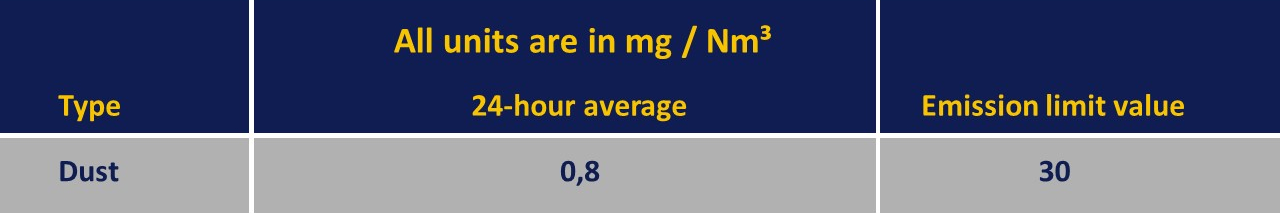

To avoid unplanned downtime, it is highly important to strictly monitor the effectivity of the Kiln and the connected dust collector. For the main dust collector, you should monitor if you are below your emission limit value. A common practice is to define your 24-hour average emission value and look for spiking numbers if it gets above-average value. In the figure below you find an example of values linked to the Kiln and its dust collector, and those values are based on a real cement plant company.

The value of 30 mg/Nm³ illustrates the maximum limit of emissions, that this company is allowed to have as an average within 24 hours. Their 24-hour average value of 0,8 mg/Nm³ shows fine control over dust emissions.

2. Scheduling and lead time

If you are experiencing regular spiking values, it might indicate some form of damage in the dust collector, which should be followed by scheduling maintenance. This maintenance should be scheduled at least 6 months in advance, where the lead time of your supplier needs to be taken into consideration.

Based on the size of the dust collector it might take different amounts of time to conduct maintenance. In some cases, the maintenance of the main dust collector might take one week, but in other cases, it might take even a whole month.

3. Long filter lifetime

The reason for emission spikes could relate to filters that are not fully suitable to be equipped into the main dust collector. Choosing filters with a long life span could reduce the number of times maintenance; which would lower the energy costs.

In case you are interested in learning about real-life results in terms of filter´s longer life cycle, you are welcome to read our case study here.

4. Filter bag vs. pleated bag

In terms of longevity and effectivity of your filters, it also depends on the type of filter you are using. There have been several cases where replacing filter bags with pleated bags made a positive impact on cement plant operations.

If you are interested in learning the difference between filter bag and pleated bag you are welcome to read a case study here.

5. Corrosion

Sometimes an overlooked reason for an increased emission level could be corrosion. This might be a result when alternative fuels are used, or if your dust collector is situated outside; and is not correctly equipped to withhold weather conditions.

If you are experiencing issues with corrosion on your filter cartridges, there are two solutions you could consider:

If the operating temperature of your dust collector is below 70 °C or 75 °C, you can use filter cartridges with no metal components.

If the operating temperature is higher than 70 °C or 75 °C, then metal components for filter cartridges are required; a solution is to use stainless steel.

6. Maintenance services

Most of the bigger cement plants have contracts with external partners that are specialized for various types of maintenance services.

If you are interested in real-life results, we would like to encourage you to read our case study which focuses on a large cement plant.

Read our case studies in cement industry.